Faster Implementation Times, Reduced Costs, and Improved Robustness

Revolutionizing pharmaceutical manufacturing with cost-effective, scalable solutions designed for precision and sterility. Our cutting-edge line of single-use manifold technologies empowers companies to streamline their filling operations, ensuring compliance and robustness while significantly reducing capital expenditure. Phaser Solutions is at the forefront of innovation in drug product filling, offering technology that adapts to your needs.

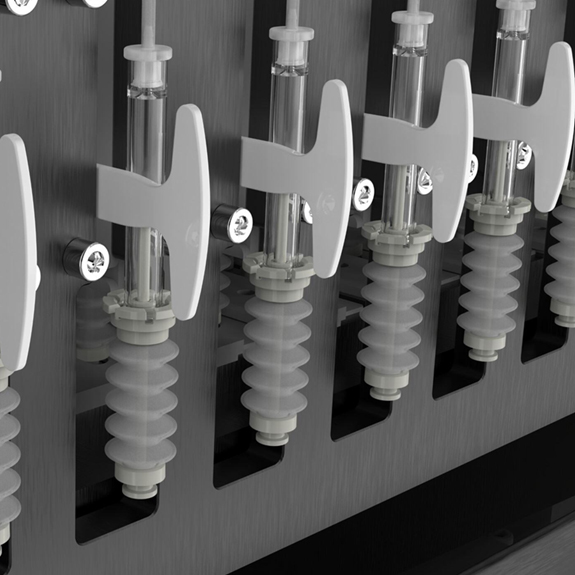

The Syn-Fill™ Advantage

Phaser Solutions’ Syn-Fill™ system represents a paradigm shift in sterile filling technology for the pharmaceutical industry. By leveraging innovative single-use manifold technologies, Syn-Fill™ addresses critical challenges faced by manufacturers, offering a streamlined approach to aseptic processing.

Accelerated Implementation

Get your production line up and running faster than ever. The Syn-Fill™ system is designed to eliminate the need for complex cleanroom setups and lengthy installation processes. Save years of setup time and bring your products to market quicker.

Read MoreLower Implementation Costs

Eliminates $1M+ in engineering and infrastructure expenses for cleanrooms, and support utilities.

Read MoreSynchronous High-Throughput

Realize higher throughput due to pre-cleaned/sterilized closed process manifold, fully assembled containers, and Synchronous filling.

Read MoreReduced Cleanroom Dependency

Closed-system processing enables use in lower-classification areas without risk to product.

Read MoreReduced Facility Footprint

Compact and portable, Syn-Fill™ fits seamlessly into existing lab and production suites spaces, reducing the need for costly grade B cleanrooms. Its mobility ensures easy integration and scalability to meet your evolving needs.

Read MoreLess Expertise Required

Simplify operations with intuitive, user-friendly designs. Syn-Fill™ reduces the need for highly specialized staff, enabling your team to focus on core processes while ensuring accurate, sterile filling.

Read MoreSimplified Operations

Pre-sterilized manifolds and disposable flowpaths minimize process steps and complexity.

Read MoreImprove Production Yield by 10-30%

Use pre-filled syringes to eliminate the need for overfilling your product and improve your production yields by 10-30% without compromising container integrity. With the innovative sealing of the tip and secondary enclosure via the bellows, our pre-filled syringes are suitable even down to ultra-low temperatures).

Read MoreIn-Process Mixing

No external mixing required. In-process mixing occurs during manifold degassing without extra steps, and synchronous filling ensures uniform drug concentration across the batch.

Read MoreTemperature Sensitive Filling Operations

Supports cold-room integration for sensitive biologics and short process durations

Read MoreReduced QC Sampling

Increase batch uniformity and reduce material waste. With Syn-Fill™, all units are filled simultaneously, maintaining consistent quality from start to finish. Experience unmatched efficiency and reliability for small batch production.

Read MoreReduced CQV Requirements

Simplify or eliminate equipment qualification, environmental qualification, and cleaning and sterilization validation

Read MoreReduced Headcount

With the simplicity of system implementation, functionality, and operator use; fewer personnel with less isolator and cleanroom specific knowledge are needed

Read More